China Factory

JOBO Factory: Your Trusted Partner in E-Bike Manufacturing

JOBO is one of China's top e-bike manufacturers, located in Jinhua, Zhejiang Province.

Our 50,000㎡ factory integrates frame production, automated painting lines, and modern assembly workshops, ensuring full control over each stage of manufacturing.

Equipped with three advanced e-bike assembly lines, JOBO delivers up to 300,000 electric bikes annually, supported by 16 QC testing instruments and a dedicated R&D team of 35 engineers.

Customization & Innovation

Flexible OEM & ODM E-Bike Solutions

Professional R&D Team

35 Engineers Driving E-Bike Innovation & Technology Upgrades

Innovation is the foundation of JOBO's success.

Our R&D department, composed of 35 professional engineers, focuses on motor technology, intelligent control systems, frame design, and structural testing.

From concept sketches to prototype verification, every e-bike model is created through a rigorous development process — ensuring durability, ride comfort, and market adaptability.

The R&D center is equipped with advanced simulation software and physical testing instruments for torque, vibration, waterproofing, and electrical performance.

We work closely with clients to customize e-bike specifications and create unique designs that meet international standards.

Advanced Production & Quality Control

ISO9001 Certified, 5S Managed, and TUV Approved

Every JOBO e-bike is built under a strict ISO9001-certified system, supported by the 5S management method and standardized SOP production processes.

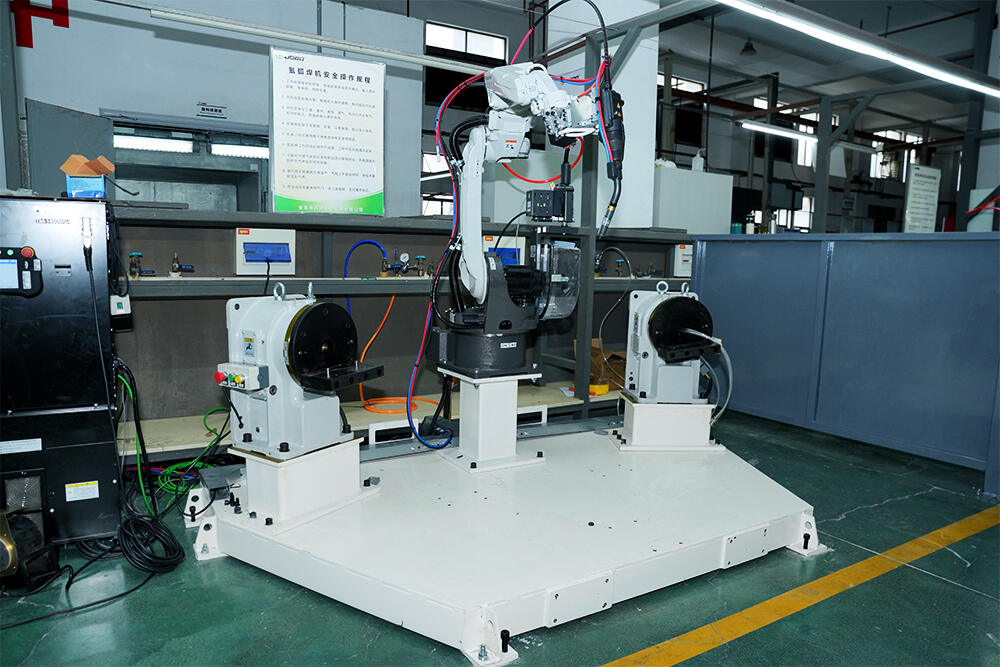

We implement multi-stage quality inspections covering frame welding, electronic integration, and final assembly.

Our 16 advanced QC instruments guarantee precision and consistency in every batch.

To date, 35 JOBO models have been awarded EN certification by TUV, reflecting our commitment to international safety and reliability.

Manufacturing Technology & Facilities

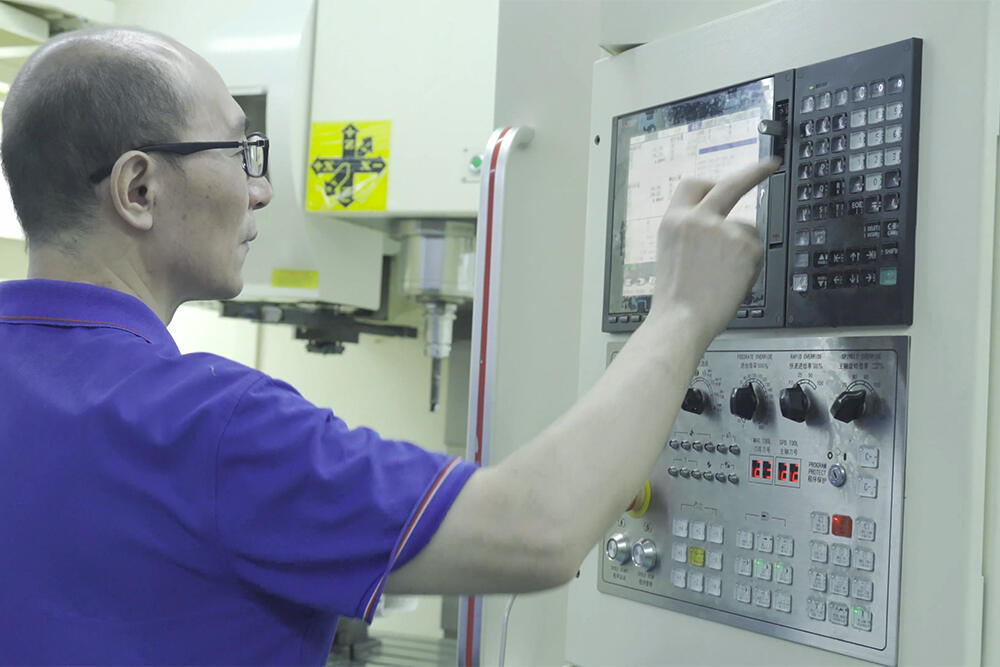

Smart Automation Meets Skilled Craftsmanship

JOBO integrates CNC machining, robotic welding, and automatic painting within its in-house frame factory.

Each step—from frame forming to powder coating—is precisely managed to deliver high strength, lightweight, and visually refined results.

This level of automation and craftsmanship allows JOBO to offer efficient, large-scale OEM e-bike production, maintaining consistent quality and competitive lead times.

Rigorous QC Team