Frame Factory

JOBO Frame Factory

Precision and Innovation at Its Core

The frame is the heart of every e-bike, and JOBO's sole-proprietorship frame factory ensures precision and uncompromised quality at every step.

Designed by an experienced engineering team, our frames optimize production efficiency and deliver superior performance and durability, forming the foundation of every high-quality e-bike.

From Raw Material to Finished Frame

As a premium e-bike frame manufacturer, we transform high-quality aluminum alloy with precision CNC cutting and robotic welding, apply durable automated coatings, and enforce rigorous quality control to deliver robust frames for global OEM, ODM, and JOBOBIKE brands.

Robotic CNC Cutting – Precision Starts Here

At JOBO Frame Factory, robotic CNC cutting machines deliver millimeter-level precision to every frame component.

Using advanced sensors and laser-guided systems, the machines ensure consistent tube geometry, smooth edges, and accurate alignment, minimizing material waste and boosting production efficiency.

This automated cutting process is the first step toward building high-strength, perfectly fitted e-bike frames that meet global quality standards.

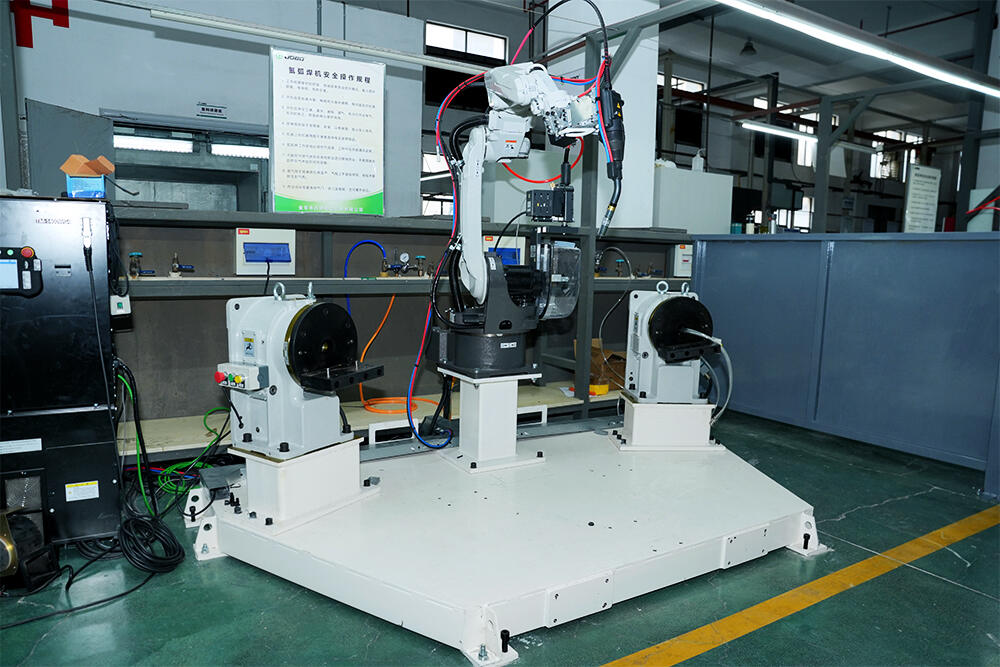

Robotic Welding – Strength with Consistency

Welding defines the strength and reliability of an e-bike frame.

Our robotic welding systems guarantee uniform seams and exceptional structural integrity, eliminating variations common in manual welding.

Every weld is tested to withstand high stress and vibration, ensuring the frame's long-term durability and smooth ride performance.

This process not only enhances mechanical strength but also gives each frame a clean, premium appearance.

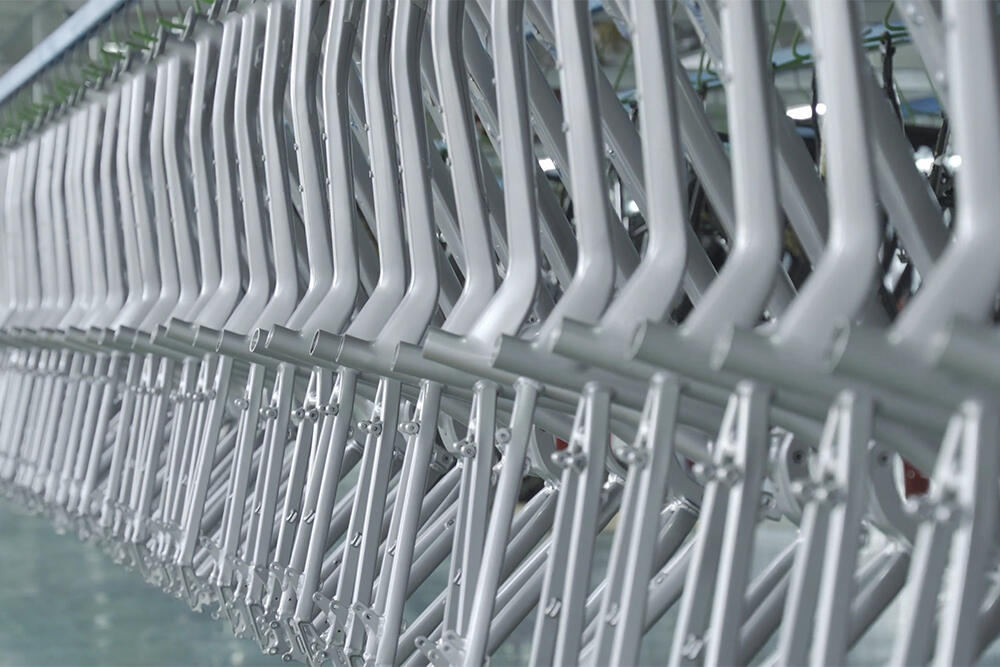

Automated Coating Line – Flawless Finish, Distinct Colors, Lasting Protection

JOBO's fully automated powder coating line delivers both visual excellence and long-lasting protection for every e-bike frame.

The entire process — from surface pre-treatment to electrostatic spraying and high-temperature curing — is precisely controlled to ensure a smooth, uniform finish that resists corrosion, UV fading, and scratches.

What sets JOBO apart is our advanced color separation technology, enabling multi-tone and gradient finishes that elevate the appearance of each frame.

Whether it's a matte texture, a metallic sheen, or a custom two-tone combination, our coating system brings your brand's design vision to life with precision and consistency.

This automated process not only enhances aesthetic appeal and durability but also supports eco-friendly production, minimizing material waste and reducing emissions.