QC Labs

Professional QC Labs

At JOBO, quality begins in the lab. Our dedicated QC Labs serve as the backbone of our quality assurance system—delivering cutting-edge multi-axis testing, precision environmental simulation, accelerated fatigue validation, and AI-powered data traceability. Together, these systems ensure full compliance with global standards while optimizing product reliability and accelerating e-bike development.

Rigorous Quality Assurance & Compliance Hub

Frame Horizontal Force and Vertical Force Fatigue Testing Machine

Evaluates the structural durability of frames under cyclic horizontal and vertical loading to simulate real-world stress conditions and assess fatigue life.

Frame Front-to-Back Jitter Testing Machine

Simulates and measures front-to-back oscillatory motion (jitter) on frames to validate stability and resistance to dynamic vibrational loads.

Computer-Controlled Disc Brake Fixed Seat Fatigue Testing Machine

Conducts automated fatigue tests on disc brake assemblies, applying controlled cyclic forces to the fixed seat to evaluate wear, deformation, and failure modes.

Complete Bike Testing Machine

Performs integrated performance, durability, and safety assessments on full bikes under simulated operational conditions (e.g., powertrain, suspension, and braking systems).

Battery Test System + Thermal Shock Testing Machine

Combines electrochemical performance evaluation of batteries with rapid temperature cycling (thermal shock) to test reliability under extreme thermal gradients and operational stress.

Magnetic Powder Dynamometer

Measures torque, power, and rotational speed of motors/engines using magnetic particle braking, enabling load simulation and efficiency analysis.

Frame and Fork Impact Testing Machine

Subjects frames and fork assemblies to controlled impact loads to assess structural integrity, crack resistance, and energy absorption capacity.

Single-Arm Drop Testing Machine

Simulates free-fall impacts on components or products from predefined heights to evaluate mechanical robustness and failure thresholds.

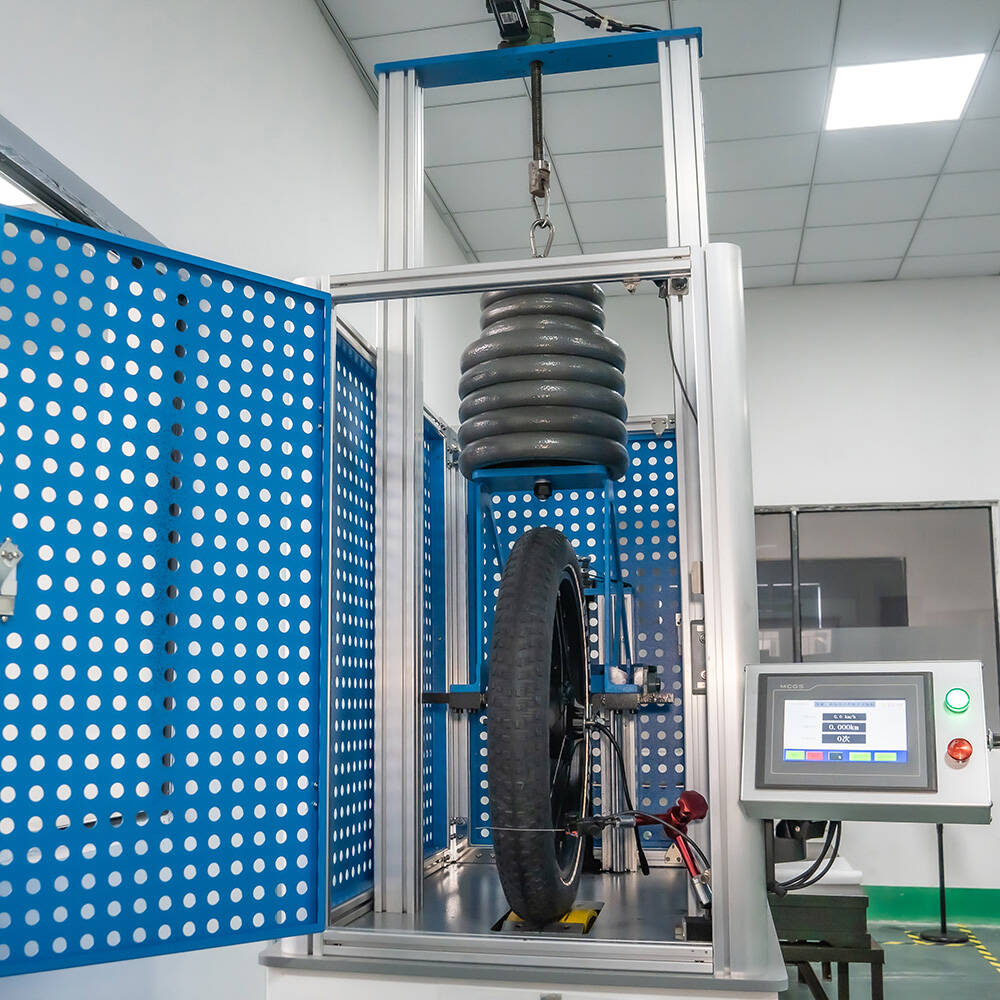

Wheel Set Fatigue Testing Machine

Applies cyclic rotational and axial loads to wheel assemblies to test fatigue resistance, bearing durability, and deformation under prolonged stress.

Industrial Water-Cooled Unit

Provides precise temperature regulation via water-based cooling for high-power testing equipment, ensuring thermal stability during prolonged operations.

Constant Temperature and Humidity Test Chamber

Maintains stable environmental conditions (temperature/humidity) to evaluate material behavior, component performance, and aging under controlled climatic exposure.

Thermal Shock Testing Machine

Rapidly alternates between extreme high and low temperatures to test material/component resilience to thermal stress, phase changes, and delamination.

Advanced Testing Equipment & Capabilities

.jpg)

IQC (Incoming Quality Control)

Raw materials and components are pre-checked, suppliers audited, non-destructive testing applied — supply-chain risks mitigated early.

.jpg)

IPQC (In Process Quality Control)

Real-time monitoring via SPC (Statistical Process Control) and automated sampling during production to catch deviations immediately.

.jpg)

FQC (Final Quality Control)

Finished bikes or frames undergo full functional, cosmetic, and regulatory tests with batch traceability, ensuring only qualifying units ship.

.jpg)

QA (Quality Assurance)

Systemic oversight with audits, CAPA (Corrective & Preventive Actions), continuous improvement in place.

Why JOBO QC Labs Stand Out?

JOBO QC Labs combine cutting-edge equipment, structured QC processes, and AI-powered data traceability to deliver reliable, high-precision testing.

Comprehensive Testing Capabilities: structural fatigue, jitter, brake fatigue, battery thermal shock, complete bike, impact & drop, wheel endurance, environmental simulation.

Structured QC System: IQC → IPQC → FQC → QA ensures all components and bikes are thoroughly verified.

Smart-Powered Traceability: every test is logged and traceable, providing clients full quality visibility.

Global Compliance: ISO-aligned procedures ensure products meet international standards for OEM & ODM e-bikes.

Accelerated Product Development: rapid and accurate testing reduces time-to-market without compromising quality.