The electric bike industry has seen explosive growth, but no segment is as demanding as the Mountain Electric Bike (eMTB) category. Whether you are a rider looking for adventure or a brand seeking a reliable manufacturing partner, understanding the engineering behind these machines is crucial.

At JOBO Technology, we don’t just assemble bikes; we engineer them. With years of experience in OEM/ODM manufacturing, we break down what makes a high-quality eMTB, from frame geometry to motor torque, and why manufacturing precision matters.

What is a Mountain Electric Bike (eMTB)?

A mountain electric bike (eMTB) is a robust bicycle designed for off-road cycling that integrates an electric motor and battery to assist the rider’s pedaling power. Unlike standard city e-bikes, eMTBs feature reinforced frames, high-torque motors, wider tires, and advanced suspension systems to handle rough terrains like steep inclines, dirt trails, and rocky paths.

For manufacturers like JOBO, creating an eMTB isn’t just about adding a motor to a bike; it requires redesigning the frame geometry to handle the added weight and stress of off-road riding while ensuring stability and safety.

Main Types of Mountain Electric Bikes

When selecting an eMTB, understanding the chassis type is the first step. Here are the three main categories we manufacture:

Hardtail Electric Mountain Bikes

A Hardtail eMTB features suspension only in the front fork, with a rigid rear frame.

- Pros: Lighter weight, better pedaling efficiency on climbs, and lower maintenance costs.

- Best For: Fire roads, light trails, and mixed commuting.

- Manufacturing Insight: At JOBO, our hardtail frames utilize hydroformed aluminum tubing to maximize stiffness without adding unnecessary weight.

Full-Suspension Electric Mountain Bikes

A Full-Suspension eMTB (or “Full-Sus”) includes both front and rear shock absorbers.

- Pros: Superior traction, comfort, and capability on technical, rocky descents.

- Best For: Technical trails, downhill riding, and enduro racing.

- Manufacturing Insight: Producing full-suspension frames requires high-precision CNC machining for the pivot points and linkage systems to ensure smooth operation and durability.

Fat Tire Mountain eBikes

These bikes feature oversized tires (typically 4.0 inches or wider) run at low pressure.

- Pros: Unmatched grip on soft surfaces like sand, snow, and mud.

- Best For: Adventure riding in extreme weather conditions.

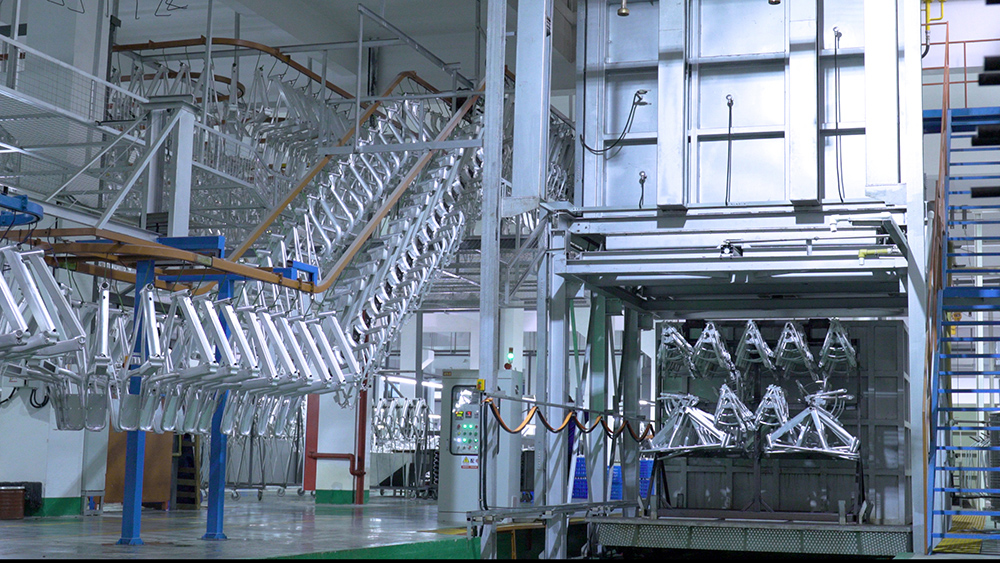

The Engineering Behind JOBO eMTB Frames

Why do some eMTBs last for years while others crack under stress? The secret lies in the manufacturing process. As a premier manufacturer, JOBO Technology prioritizes structural integrity through three key processes:

1. Material Selection (Aluminum 6061)

We primarily use 6061 Aluminum Alloy. This material offers the perfect balance of strength, weight, and formability. It resists corrosion and provides a responsive ride feel essential for mountain biking.

2. T4 and T6 Heat Treatment

This is a critical step many budget manufacturers skip.

- T4 Treatment: The frame is heated and naturally cooled to allow for alignment adjustments.

- T6 Treatment: The frame is artificially aged in a furnace to harden the alloy.

Why it matters: Without T6 heat treatment, an aluminum frame lacks the structural memory and strength to withstand the high impact of mountain biking. All JOBO frames undergo rigorous heat treatment.

3. ISO Testing Standards

A design is only as good as its test results. Every JOBO eMTB prototype undergoes fatigue testing compliant with ISO standards. This includes simulating thousands of cycles of vertical force, pedaling force, and impact stress to ensure the frame will not fail in real-world scenarios.

Hardtail vs. Full Suspension eMTB: Which One Do You Need?

This comparison helps clarify which type suits your specific market or riding style.

| Feature | Hardtail eMTB | Full-Suspension eMTB |

|---|---|---|

| Weight | Lighter | Heavier (due to rear shock & pivots) |

| Cost | More Affordable | Higher Cost |

| Maintenance | Low (fewer moving parts) | High (pivot bearings & shocks) |

| Comfort | Good on smooth trails | Excellent on rough terrain |

| Traction | Lower on loose rocks | Higher (rear wheel tracks ground) |

JOBO Recommendation: For rental fleets or entry-level markets, Hardtails are ideal due to low maintenance. For premium performance markets, Full-Suspension is the standard.

Future Trends in eMTB Manufacturing

As a forward-thinking manufacturer, JOBO is observing these emerging trends:

- Lightweight eMTBs (SL): Using smaller batteries and lighter motors to create e-bikes that feel like traditional mountain bikes.

- SUV eBikes: The crossover segment. These are full-suspension mountain bikes equipped with lights, racks, and fenders for daily commuting and weekend adventure.

- Smart Connectivity: Frames designed to house IoT modules for GPS tracking and anti-theft systems.

Contact & OEM Support

-

📞 Phone: +86 198 8486 5520

-

📧 Email: info@jobobikes.com / sale09@jobobikes.com

-

🌐 Website: https://www.joboev.com

Frequently Asked Questions (FAQ)

Q: Are electric mountain bikes waterproof?

Most quality eMTBs, including those manufactured by JOBO, have IP65-rated electrical components. This means they are resistant to water jets and rain, but they should not be submerged in water or pressure washed directly on the electronics.

Q: How long does an eMTB battery last?

A high-quality Lithium-ion battery (using Samsung or LG cells) typically lasts for 800 to 1,000 charge cycles before capacity drops significantly. In terms of range, a 720Wh battery can typically cover 50-100km depending on terrain and assist level.

Q: Why is frame geometry important for eMTBs?

eMTBs are heavier than regular bikes. Specific geometry—such as a slacker head tube angle and a lower bottom bracket—is engineered to keep the bike stable at high speeds and prevent “looping out” (the front wheel lifting) on steep climbs.

Conclusion

Choosing the right Mountain Electric Bike goes beyond looking at the motor power; it is about the quality of the frame engineering, the precision of the welding, and the reliability of the components.

At JOBO Technology, we combine advanced manufacturing techniques with a passion for cycling to produce eMTBs that stand the test of time. Whether you are a brand looking for an OEM partner or a distributor seeking the latest models, quality manufacturing is the foundation of a great ride.

Looking for a reliable eBike manufacturer? Contact JOBO Technology today to discuss your eMTB requirements.