JOBO QC Labs is a dedicated quality assurance and compliance hub operated by an experienced electric bike manufacturer and OEM supplier. It validates electric bike safety, structural durability, and regulatory readiness through real-world simulation, environmental stress testing, and long-term fatigue validation for global and European markets.

How Does JOBO QC Labs Ensure Electric Bike Quality?

JOBO QC Labs ensures electric bike quality through a combination of component-level testing, structural validation, environmental simulation, and full-bike performance assessment.

Tests are designed to replicate real-world urban riding conditions, extreme environments, and long-term usage before any electric bike reaches the market.

What Types of Tests Are Conducted in JOBO QC Labs?

JOBO QC Labs uses state-of-the-art equipment to perform comprehensive quality checks:

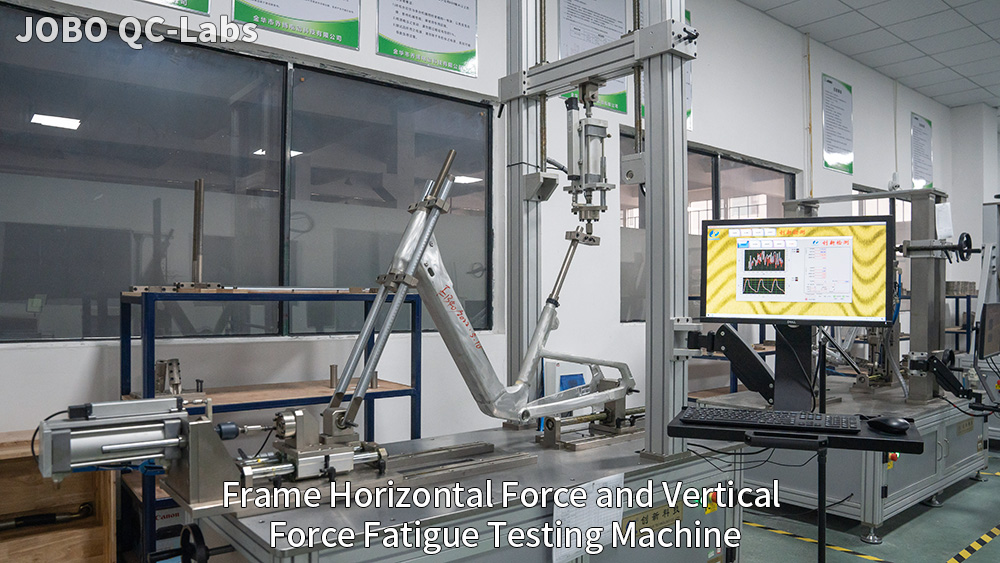

- Frame Horizontal & Vertical Force Fatigue Testing – simulates cyclic stresses to evaluate long-term structural durability

- Frame Front-to-Back Jitter Testing – validates vibration resistance and stability under dynamic loads

- Impact & Drop Testing – assesses crack resistance, energy absorption, and mechanical robustness

- Braking System Fatigue Testing – ensures hydraulic disc brakes maintain reliability under repeated forces

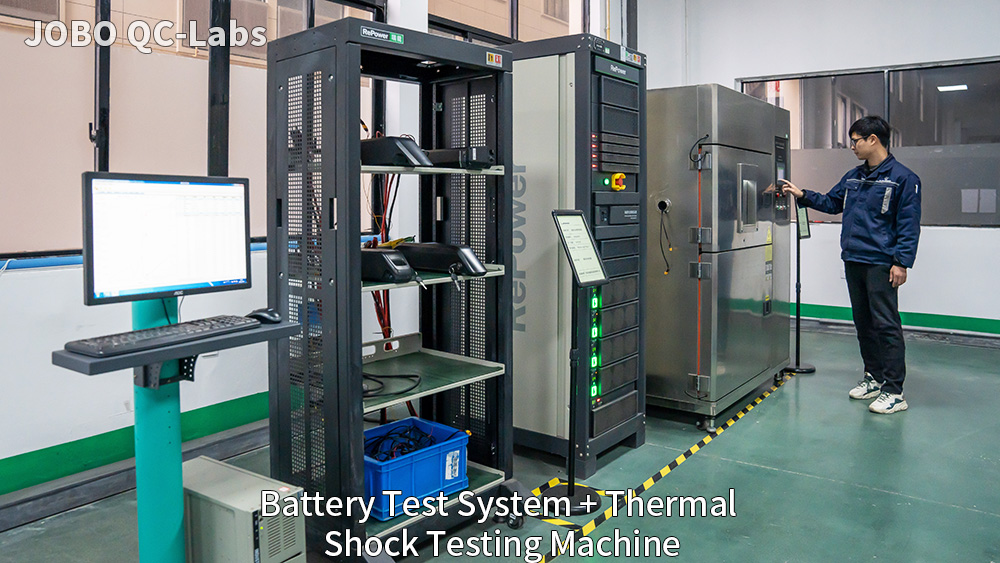

- Battery Performance & Thermal Shock Testing – evaluates electrical stability and resilience under extreme temperature changes

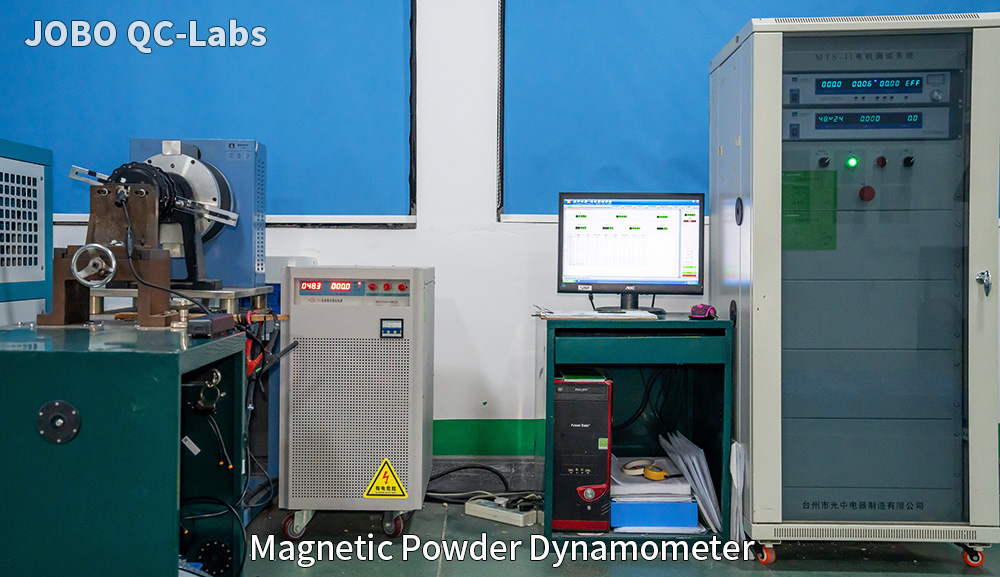

- Motor Performance Measurement – measures torque, power, speed, and efficiency using magnetic powder dynamometers

- Wheel Set Fatigue Testing – confirms bearing durability, rim stability, and resistance to deformation

- Complete Bike Testing Machine – assesses integrated systems, including powertrain, suspension, and braking

This multi-layered testing ensures both individual components and full bikes meet safety, reliability, and performance standards.

How Are Electric Bike Frames Tested for Strength and Durability?

Frames undergo horizontal and vertical fatigue testing to simulate years of riding stress.

Front-to-back jitter testing validates stability under continuous vibrations, such as uneven roads, curbs, and traffic stops.

Impact and drop tests evaluate crack resistance, energy absorption, and failure thresholds, ensuring the bike frame can endure real-world usage.

How Are Braking Systems Validated for Urban Safety?

Disc brake assemblies are tested using computer-controlled fatigue machines that apply repeated cyclic forces.

This testing measures:

- Long-term wear

- Structural deformation

- Braking reliability under urban stop-and-go conditions

Reliable braking performance is critical for daily commuters, fleet operations, and regulatory compliance.

How Are Electric Bike Batteries Tested for Safety and Thermal Reliability?

Batteries are tested with a combined electrochemical and thermal shock system.

This validates:

- Charge and discharge performance

- Stability under rapid temperature fluctuations

- Long-term operational reliability

Testing reduces battery-related failures in both extreme cold and heat.

How Is Motor Performance Measured and Verified?

JOBO measures torque, rotational speed, power output, and efficiency using magnetic powder dynamometers.

This ensures mid-drive and hub motors deliver smooth, consistent assistance while maintaining CE-compliant performance.

How Are Wheels Tested for Long-Term Urban Riding?

Wheel assemblies undergo cyclic rotational and axial load testing to evaluate:

-

Bearing durability

-

Rim deformation

-

Resistance to prolonged stress

This ensures reliability for daily commuting and shared fleet programs.

How Does JOBO Simulate Environmental and Climate Conditions?

JOBO uses:

-

Constant temperature and humidity chambers – evaluate material aging and component performance

-

Thermal shock testing machines – rapidly cycle between extreme high and low temperatures

This guarantees electric bikes can withstand rain, snow, and extreme seasonal changes in European and global markets.

Why Is QC Testing Critical for European Market Compliance?

European regulators require electric bikes to meet high safety, durability, and reliability standards.

JOBO QC Labs provides the technical validation needed for CE conformity, including:

-

Frame and component structural integrity

-

Electrical and thermal safety

-

Full-bike system performance

-

Long-term durability

This reduces regulatory risk for distributors and OEM partners.

Why Does Advanced QC Capability Matter for OEM and Fleet Partners?

Rigorous laboratory testing helps OEM brands and fleet operators:

-

Reduce after-sales risks

-

Maintain consistent product quality

-

Meet long-term reliability expectations

-

Enter premium and European markets with confidence

How JOBO QC Labs Strengthens Long-Term Manufacturing Trust

By validating products under real-world stress before mass production, JOBO ensures that electric bikes are durable, safe, and compliant.

The QC Labs acts as the backbone of JOBO’s quality assurance system, setting it apart from ordinary manufacturers.

Frequently Asked Questions

Q1: How does JOBO QC Labs ensure electric bike quality?

A: Through structural fatigue testing, component validation, environmental simulation, and complete bike system testing under real-world conditions.

Q2: What types of tests are conducted in JOBO QC Labs?

A: Frame fatigue, jitter/vibration, impact/drop, braking system fatigue, battery thermal, motor performance, wheel fatigue, and full bike testing.

Q3: How are electric bike batteries tested for safety?

A: Using electrochemical performance systems combined with thermal shock testing to validate stability under extreme temperatures.

Q4: How does JOBO support European market compliance?

A: By validating structural integrity, electrical safety, thermal reliability, and durability to meet CE conformity standards.

Q5: Why is QC testing important for OEM and fleet partners?

A: QC testing reduces risk, improves product consistency, and ensures reliability in premium urban mobility markets.

Contact & OEM Support

-

📞 Phone: +86 198 8486 5520

-

📧 Email: info@jobobikes.com / sale09@jobobikes.com

-

🌐 Website: https://www.joboev.com

JOBO QC Labs supports custom OEM production, mid-drive optimization, and CE-compliant fleet deployment.