Electric bike frame manufacturing directly determines riding safety, durability, and performance. As a professional e‑bike frame manufacturer in China, JOBO operates a fully in‑house, CNC‑driven and ISO‑certified production process. From tube cutting and forming to welding, heat treatment, and automated coating, every step follows a standardized sequence designed for OEM & ODM e‑bike manufacturing and global compliance.

How Does JOBO Manufacture High‑Quality E‑Bike Frames?

JOBO produces electric bike frames through a complete closed‑loop process that integrates CNC machining, robotic laser cutting, automated welding, aluminum heat treatment, and precision inspection. This ensures consistent geometry, structural strength, and EU‑compliant quality for large‑scale e‑bike production.

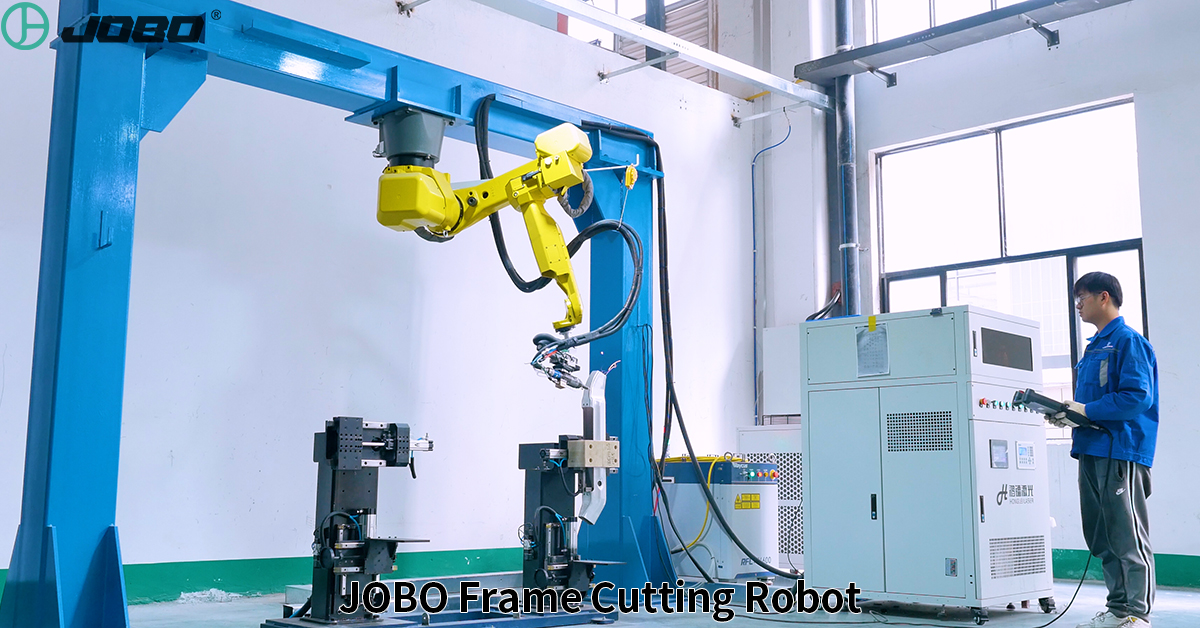

Tube Cutting and CNC Blanking Process

Frame production starts with precise tube preparation to guarantee dimensional accuracy and material stability.

CNC Cutting & Machining Equipment

-

CNC blanking machine

-

CNC machining center

-

CNC lathe

-

Robotic 3D laser cutting machine

These machines ensure accurate tube length, interface openings, and joint geometry, forming the foundation of high‑precision e‑bike frame manufacturing.

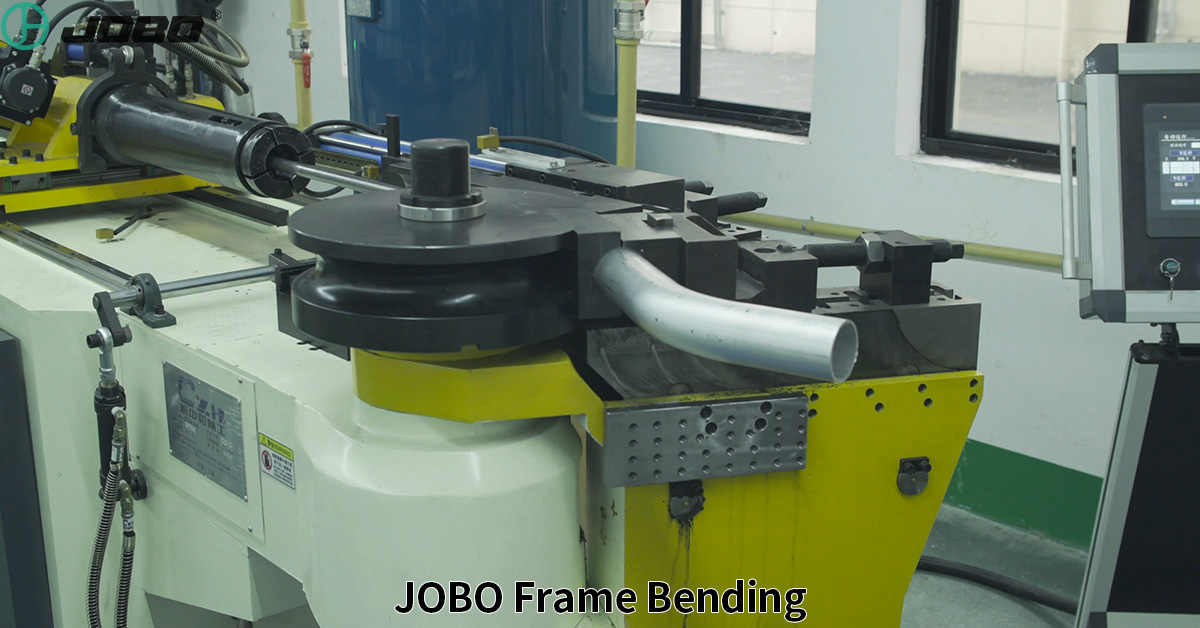

Tube Forming, Bending and Structural Shaping

After cutting, tubes are shaped to meet frame design and strength requirements.

Automated Tube Forming Technology

-

Automatic tube shrinking machine

-

CNC tube bending machine

-

Rear triangle CNC tube bending machine

-

Two‑axis hydraulic hard mold press

This stage ensures uniform curvature, wall‑thickness control, and symmetry for complex aluminum e‑bike frames.

Arc Milling, Slotting and Interface Preparation

To ensure perfect joint alignment and strong weld penetration, JOBO performs dedicated CNC milling and slotting operations.

Precision Arc & Slot Machining

-

Horizontal arc milling machine

-

Horizontal arc punching machine

-

Slotting & duckbill integrated cutting machine

-

Middle tube slot cutting machine

These processes improve welding strength and overall frame rigidity.

Tube Surface Grinding and Cleaning

Before welding, tube surfaces are fully prepared to remove oil, burrs, and oxidation.

Surface Preparation Process

-

Automatic grinding machine

-

Tube belt sanding machine

-

Tube cloth‑wheel polishing machine

-

Tube cleaning line

Clean and uniform surfaces ensure stable welding quality and corrosion resistance.

Welding Preparation and Tooling Management

Professional welding requires standardized tooling and controlled environments.

Welding Support Systems

-

Mold and fixture warehouse

-

Hard brazing area

These systems ensure consistent frame geometry and repeatable welding quality across OEM orders.

Frame Welding and Assembly Lines

JOBO follows a strict welding sequence to maintain dimensional accuracy.

Standardized Welding Lines

-

Parts welding line

-

Front triangle welding line

-

Front triangle geometry comparison

-

Rear triangle welding line

-

Frame assembly, welding, and correction

Dedicated fixtures and SOP‑controlled welding ensure structural strength and consistency.

Frame Alignment, Calibration and Measurement

After welding, each frame undergoes correction and inspection.

Geometry Control & Inspection

-

Frame correction platforms

-

Alignment inspection equipment

-

Dimensional measurement

-

Down tube battery box inspection

This ensures compatibility with motors, batteries, and braking systems in electric bike assembly.

Aluminum Heat Treatment: T4 and T6

Heat treatment is essential for aluminum e‑bike frame durability and fatigue resistance.

Heat Treatment & Hardness Testing

-

T4 heat treatment furnace

-

T6 heat treatment furnace

-

Hardness testing equipment

These processes significantly enhance mechanical strength and long‑term riding performance.

Post‑Heat Treatment Precision Machining

After heat treatment, functional interfaces are machined to final tolerances.

Functional CNC Operations

-

Head tube inner diameter boring and chamfering

-

Middle tube reaming machine

-

Bottom bracket thread tapping machine

-

Disc brake mounting surface milling machine

These steps ensure precise installation of bearings, motors, and braking components.

Frame Surface Finishing and Appearance Control

Before painting, frames undergo detailed surface finishing.

Appearance Grinding & Detail Polishing

-

Complete frame appearance grinding

-

Fine detail polishing

This stage guarantees a premium surface quality for branded electric bike frames.

Automated Coating & Painting Process

JOBO operates a fully automated coating system for consistent and eco‑friendly finishes.

Automatic Painting & Powder Coating Lines

-

Automatic phosphating (skin film) line

-

Frame conveyor line

-

Painting loading area

-

Automatic electrostatic powder coating machine

-

Powder curing oven line

-

Automatic liquid paint baking line

-

Touch‑up painting

-

Decal application line

-

Automatic metallic gold spray

Automated coating ensures uniform thickness, corrosion resistance, and color consistency.

Finished Frame Inspection & Quality Assurance

Every completed frame is inspected before entering electric bike assembly.

Final Quality Control

-

Finished frame inspection area

-

Appearance inspection

-

Dimensional verification

-

Full‑frame inspection platform

CNC‑Driven E‑Bike Frame Manufacturing at JOBO

From CNC tube cutting and robotic welding to heat treatment, precision machining, and automated coating, JOBO’s electric bike frame manufacturing system reflects the capabilities of a modern e-bike frame factory in China, providing dependable OEM solutions for international electric bike brands.

Contact & OEM Support

-

📞 Phone: +86 198 8486 5520

-

📧 Email: info@jobobikes.com / sale09@jobobikes.com

-

🌐 Website: https://www.joboev.com

FAQ: E-Bike Frame Manufacturing

What materials are used for JOBO e-bike frames?

Most JOBO e-bike frames are manufactured using high-grade aluminum alloys such as 6061 and 7005, selected for strength-to-weight ratio, weldability, and heat treatment compatibility.

Why are T4 and T6 heat treatments important for aluminum e-bike frames?

T4 and T6 heat treatments restore material strength after welding, improve fatigue resistance, and ensure long-term structural stability for electric bike frames.

How does robotic welding improve frame quality?

Robotic welding ensures consistent weld penetration, uniform bead geometry, and reduced human error, resulting in higher frame alignment accuracy and repeatable quality.

What quality inspections are performed before frame painting?

Before painting, frames undergo alignment checks, dimensional measurement, hardness testing, and full-frame inspection to verify tolerance and structural integrity.

How is surface finish controlled before powder coating or painting?

Frames are polished, fine-ground, chemically treated (e-coating / conversion coating), and cleaned to ensure strong paint adhesion and corrosion resistance.

Can JOBO customize frames for OEM and ODM e-bike brands?

Yes. JOBO supports OEM and ODM projects including geometry customization, battery integration, welding fixtures, surface finish options, and branding.